YFA’s new automated machine.

YFA’s new automated machine.

Production capacity has 5 times increasing after using our new CNC Automatic Drilling Machine.

Our new friend, a CNC Automatic

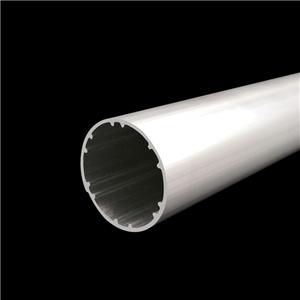

Some of our aluminum curtain rail or aluminum extrusion profiles or aluminum louver and aluminum balustrade need to be punched holes or drilled holes in specific location to help customers have an easier assemble and installation process when they receive our products.

Actually we already have drilling machine in YFA factory, but for the tapping holes, we need to tap after drilling, it means we should use 2 different machines and with 2 production process.

But in last month, we received a special aluminum curtain rail order with 180,000 tapping holes from one of our customer in Switzerland.

To make sure we can help to finish this order in our standard lead time. We must do something to improve our production capacity.

So a new friend, a CNC Automatic Drilling Machine is coming.

With the automated produce, our production capacity has been increased 5 times! Our daily production capacity for produce tapping holes is from 2,000 to 10,000 pieces.

Automatic produce is not a new but must the most important in a modern city, so YFA is constantly improving and growing. YFA company is still tries our best to produce products and help and serve our customers and friends.